Used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. Centrifugal pump acts as a reverse of an inward radial flow reaction turbine. Flow in the pumps is in the radial outward direction.

Centrifugal pump works on the principal of forced vortex flow which means that when a certain mass of liquid is rotated by an external torque, the rise in pressure head of the rotating liquid takes place. The rise in pressure head at any point of the rotating liquid is proportional to the square of tangential velocity of the liquid at that point.

Rise in pressure head = V2/2g or w2r2/2g

The pump casing guides the liquid from the suction connection to the center, or eye, of the impeller. Material of the casing depends on the type of liquid being handled. For example in case of sea water brass is used and in case of fresh water stainless steel is used. The vanes of the rotating impeller impart a radial and rotary motion to the liquid, forcing it to the outer periphery of the pump casing where it is collected in the outer part of the pump casing called the volute. The volute is a region that expands in cross-sectional area as it wraps around the pump casing. The purpose of the volute is to collect the liquid discharged from the periphery of the impeller at high velocity and gradually cause a reduction in fluid velocity by increasing the flow area. This converts the velocity head to static pressure. The fluid is then discharged from the pump through the discharge connection.

Centrifugal pumps can also be constructed in a manner that results in two distinct volutes, each receiving the liquid that is discharged from a 1800 region of the impeller at any given time. Pumps of this type are called double volute pumps(Split volute pumps). In some applications the double volute minimizes radial forces imparted to the shaft and bearings due to imbalances in the pressure around the impeller.

Diffuser

Set of stationary vanes that surround the impeller. The purpose of the diffuser is to increase the efficiency of the centrifugal pump by allowing a more gradual expansion and less turbulent area for the liquid to reduce in velocity. Liquid exiting the impeller will encounter an ever increasing flow area as it passes through the diffuser. this increase in flow area causes a reduction in flow velocity, converting kinetic energy into flow pressure.

Impeller

Impellers of pumps are classified based on the number of points that the liquid can enter the impeller and also on the amount of webbing between the impeller blades.

- Single suction or double suction design :- Single-suction impeller allows liquid to enter the center of the blades from only one direction. Double-suction impeller allows liquid to enter the center of the impeller blades from both sides simultaneously.

- Open impeller :- Consists only of the blades attached to a hub. Can handle large amount of suspended solids. These are structurally weak. They are inefficient.

- Semi -open impeller :- Circular plates attached to one side of the blades. Can handle small amount of suspended solids. They have average material strength.

- Enclosed or Shrouded impeller :- Circular plates attached to both sides of the blades. They have good material strength and are very efficient.

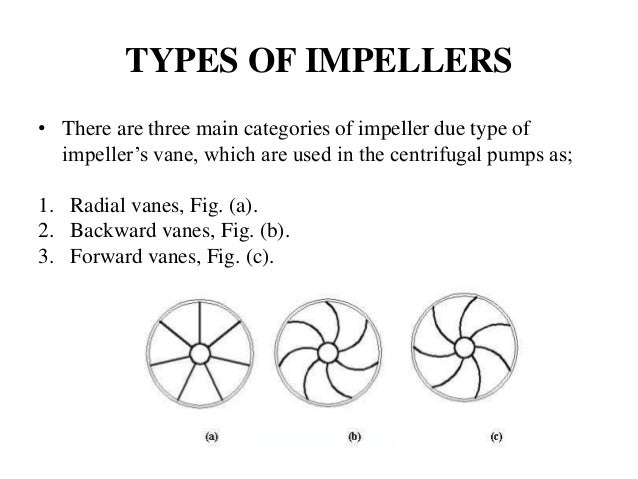

Types of impeller according to curvature of vane design:-

- Radial vanes

- Backward vanes

- Forward vanes

In case of backward vanes it is observed that no stall point is there on its characteristic curves i.e. no point on its characteristic curve on which it cannot be operated.

Forward vanes are used when the fluid concerned is air as in centrifugal fan.

Pic credit - https://nptel.ac.in/content/storage2/courses/112104117/chapter_8/8_6.html

According to the above curve the power requirement increases monotonically with an increase in discharge in the radial and forward vaned centrifugal pump. For backward curved vane centrifugal pump, if the flow rate increase/decrease from the design flow rate contrary to others, the power requirements drops. Hence vanes are curved backwards to prevent overloading.

Due to inertial effect, the liquid which is trapped between the impeller vanes is reluctant to move round with the impeller. This results in difference of pressure force across the vane. Therefore, high pressure developed in the leading side and low pressure on the trailing side. This difference is called vane loading which increases with the number of vane.

Impeller on the basis of number of blades

- 5-10 channel- best efficiency- no particle

- less than 5 channel flow with particle, eg waste water.

On the basis of flow pump divide as

- Radial flow pumps :- Liquid enters at the center of the impeller and is directed out along the impeller blades in a direction at right angles to the pump shaft.

- Axial flow pumps :- Impeller pushes the liquid in a direction parallel to the pump shaft. also called propeller pumps because the operate same as propeller of a boat.

- Mixed flow pumps :- Borrow characteristics from both radial flow and axial flow pumps. As liquid flows through the impeller of a mixed flow pump, the impeller blades push the liquid out away from the pump shaft and to the pump suction at an angle greater than 900.

- Wearing Rings :- Replaceable rings that are attached to the impeller and/or the pump casing to allow a small running clearance between the impeller and the pump casing without causing wear of the actual impeller or pump casing material. These rings are periodically replaced.

- Stuffing Box :- Simplest type of shaft seal. Cylindrical space in the pump casing surrounding the shaft. Rings of packing material are placed in this space. Packing is material in the form of rings or strands that is placed in the stuffing box to form a seal to control the rate of leakage along the shaft. The packing rings are held in place by a gland. The gland is, in turn, held in place by studs with adjusting nuts. As the adjusting nuts are tightened, they move the gland in and compress the packing. This axial compression causes the packing to expand radially, forming a tight seal between the rotating shaft and the inside wall of the stuffing box. The high speed rotation of the shaft generates a significant amount of heat as it rubs against the packing rings. If no lubrication and cooling are provided to the packing, the temperature of the packing increases to the point where damage occurs to the packing, the pump shaft, and possibly nearby pump bearings. Stuffing boxes are normally designed to allow a small amount of controlled leakage along the shaft to provide lubrication and cooling to the packing. The leakage rate can be adjusted by tightening and loosening the packing gland.

- Lantern Ring :- It is a perforated hollow ring located near the center of the packing box that receives relatively cool, clean liquid from either the discharge of the pump or from an external source and distributes the liquid uniformly around the shaft to provide lubrication and cooling. The fluid entering the lantern ring can cool the shaft and packing, lubricate the packing, or seal the joint between the shaft and packing against leakage of air into the pump in the event the pump suction pressure is less than that of the atmosphere.

- Mechanical Seal :- It consist of two basic parts, a rotating element attached to the pump shaft and a stationary element attached to the pump casing. Each of these elements has a highly polished sealing surface. The polished faces of the rotating and stationary elements come into contact with each other to form a seal that prevents leakage along the shaft.

- Simple and cheap in construction.

- No metal to metal fit.

- No valves involved in pump operation.

- Handle liquid with large amount of solids.

- Low maintenance cost.

- Cannot be operated at low capacity.

- Cannot be operated at high heads.

- Cannot handle highly viscous fluids efficiently greater than 1000 centipoise.

- Max efficiency holds over a narrow range of conditions.

- Cannot operate if %vol. of dissolved gases is greater than 5%.

- Require priming for working.

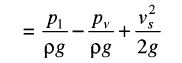

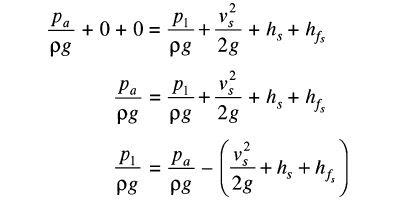

- The Net Positive Suction Head Available (NPSHA) is the difference between the pressure at the suction of the pump and the saturation pressure for the liquid being pumped.

- The Net Positive Suction Head Required (NPSHR) is the minimum net positive suction head necessary to avoid cavitation.

- If the tank is getting empty h will reduce so we will have to throttle the discharge for reducing the frictional losses.

- When stripping throttle the discharge valve not the suction valve.

- Submerge pump in tanks where more volatile substance as vapor pressure is much higher.

- On board ship boiler feed water pump kept at lower position so that it doesn't lose suction as temperature rises vapor pressure increases.

- For reducing the frictional losses pipe line must be smooth and less number of bends.

- Noise - sound like a can of marble being shaken.

- From remote operation- fluctuating discharge pressure , flow rate and pump motor current.

- Drop in pressure at the suction due to low NPSHa.

- Increase of the pressure of the pumped liquid.

- Increase in the fluid velocity at pump suction - caused by higher flow rates than the design case.

- Reduction of the flow at pump suction.

- Undesirable flow conditions caused by obstructions or sharp elbows in the suction pipe.

- Pump not selected properly. -- NPSHr > NPSHa

- Increase the pressure at the suction of the pump.

- Decreasing the temp. - large steam condensers usually sub cool the condensate to less than the saturation temp. called condensate depression, to prevent cavitation in the condensate pumps.

- Increase the suction pipe diameter.

- Reducing the number of elbow, valves and fitting in the pipe and decreasing the length of the pipe i.e. reduce head losses in the pump suction piping.

- NPSHr of a pump increases significantly as flow rate through the pump increases. So reducing the flow rate through a pump by throttling a discharge valve decreases NPSHr.

- NPSHr also depend upon pump speed. The faster the impeller rotates, greater the NPSHr.

- Horizontal misalignment - check with the help of tri square

- Angular misalignment - we use dial gauge (put dial gauge on the coupling of the motor and its pin on the pump coupling side and rotate it and then record the deflection on the dial gauge) or we can measure distance between the flanges.

- Pump fails to start pumping.

- p/p may not be properly primed.

- suction lift and delivery head too high.

- too low speed.

- wrong direction of p/p rotation.

- clogging of impeller or strainer or suction line.

- Pump working but not upto capacity and pressure.

- air leakage into p/p.

- too low speed.

- wrong direction of pump rotation.

- partial clogging of impeller.

- small impeller diameter.

- discharge head higher than anticipated.

- insufficient suction head in case of hot or volatile liquid being pumped.

- Pump takes too much of power

- too high speed.

- wrong direction of p/p rotation.

- p/p delivers too much liquid at too low head.

- shaft is bent, impeller rubs on the casing.

- too high specific gravity of the liquid being pumped.

- cavitation

- too tight packing and lack of lubrication.

- Pumps gets overheated

- rubbing b/w stationary and moving elements.

- lack of lubrication.

- very high impeller speed.

- mechanical defects such as worn out rings, bent shaft, worn out bearings, bearings not greased properly.

- Noisy operation and pump vibration

- cavitation.

- misalignment of pump shaft.

- worn out bearings.

- improper foundation.

- rubbing action b/w stationary and moving elements.

No comments:

Post a Comment